Popular Types of Metal Cutters

One of the most critical aspects of metal fabrication is the capacity to form and shape the metal parts combined with the ability to cut the metal material to make it suit the specific needs of the project. This is where metal cutters enter the picture.

Metal is among the toughest materials ever harnessed, created, and improved on the face of the planet. That’s why it’s not a big surprise that numerous special tools were also developed to cut metal.

Today, you can find and choose from a myriad of tools for cutting metal, either machine or manual-operated. But to make it easier for you to make the choice when it’s finally time to use these tools, it’s important to be familiar with their different types.

Below are the primary types of metal cutting tools you can consider to use to fabricate metal components for your future projects.

What are Metal Cutters?

Metal cutting tools have a critical role to play in the manufacturing industry. These tools include machining equipment that cuts, drills, grinds, presses, punches, and shears. Machine tools are power-driven metal forming or cutting machines used for changing workpieces into specified shapes and sizes by cutting away unwanted sections. These tools also carry out controlled electrical machinery processes such as shearing, pressing, sealing, and drawing. Metal cutting tools are also operated either with automatic control or manually.

Types of Metal Cutting Tools

You can find different types of machine tools in the market, which include thick metal cutting tools, handheld metal cutting tools, and more.

- The machines that can cut metal include machining centres, grinding machines, boring machines, millers, drilling machines, and lathes.

- The main purpose of metal cutters is to get rid of leftover materials from a manufactured metal piece with the use of shear deformation.

- Metal cutting tools have two primary types that are often used these days, namely multi-point and single-point tools.

- Multi-point tools might be a part of critical processes such as milling, drilling, and grinding, while single-point tools are mostly used to remove excess material by cutting the edges through turning, shaping, as well as other relevant procedures.

Types of Sheet Metal Cutting Tools

Below are the important cutting tools used in metalwork applications:

Cutting Taps

Machinists use cutting taps to form internal threads. These tools are suitable for getting rid of materials from the tapped hole. These cutting taps are extremely versatile and can also be used for various types of materials.

Die Cutting Machines

Die-cutting machines can cut shapes out of chipboard fabric, paper, and other kinds of materials. These are set up on the highest part of the crafting table and kept in a small spot.

Drills

Drills are primary tools used to create round holes. They can rotate and move in no time and have the ability to create holes in hard metal. Drills are also fitted with a bit. Other power drills come with a hammer function as well.

Punches

Punches are hard metal rods featuring a sharp tip at one end. The opposite end features a blunt tip and is often struck using a hammer. It’s common for carpenters to use punches to strike since these can swiftly cross the hard metal, driving objects such as nails into metal.

Reamers

Reamers are rotary tools used in metalworking. These tools are designed for enlarging the dimensions of the previously formed hole.

Types of Workshop Cutting Tools

Cutting tools turn metal into reliable precision parts used for almost anything, from car components to aircraft parts.

Machine metal cutters range from rough cutting equipment like a grinder or chop saw to production-oriented programmable machines such as the metal mill.

Below are the popular types of metal cutting tools often employed in projects at an industrial level.

Chop Saw

Chop saw wheels are rough stationery cutters that are used for cutting materials to the desired length. These chop saws feature a spinning sharpened or abrasive blade that is suspended from the arm on top of a fixed base. Once the blade is lowered, it will cut through the material that rests on the bottom during the chopping motion.

Drill Press

A drill press can bore precision holes, cut threads, and ream openings. This particular tool has an arm suspending a drill above a stationary base. The material is placed at the bottom before the drill is activated and lowered through it. A drill press lowers on a fast and hard axis and makes straight cuts precisely up and down.

Grinder

Grinders are among the handheld metal cutters that spin sharpened or abrasive discs to grind, cut, and shape materials. The portability of grinders lets them shape and chop in places where the stationary cutting tools are not able to do so.

Handheld Rotary Tools

Rotary tools have spin attachments called bits that are used to carve, cut, and ram. These handheld rotary tools often weigh a pound and due to their small attachments, these are often used to complete precision work or detail by hand.

Lathe

Lathe is the answer for those times when you might need to turn stairway posts. A machinist’s lathe serves as a wood-burning table while still giving the precision and facility required for milling metal. The fabric is first mounted at each end of the lathe. The lathe is then turned to press the material against the cutting edges while it rotates. The edges can also be manually clipped against the fabric and the cuts can also be operated using a computer input.

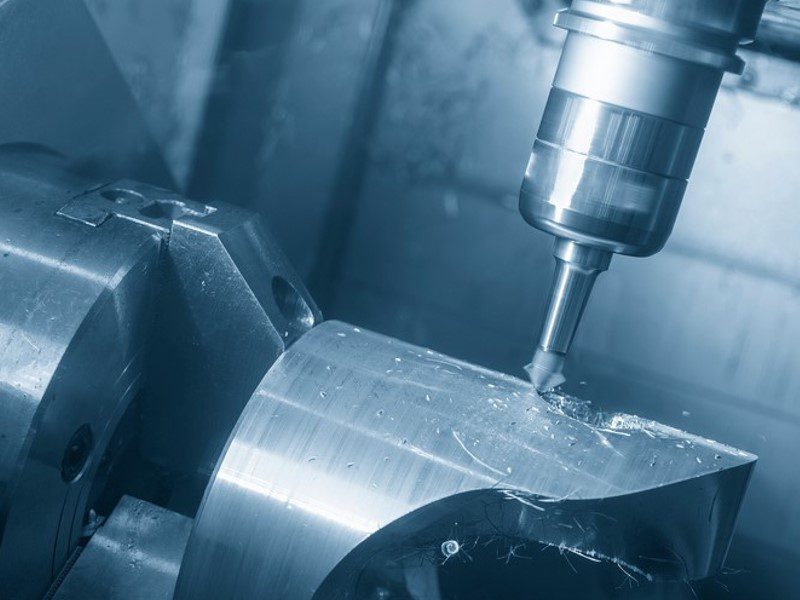

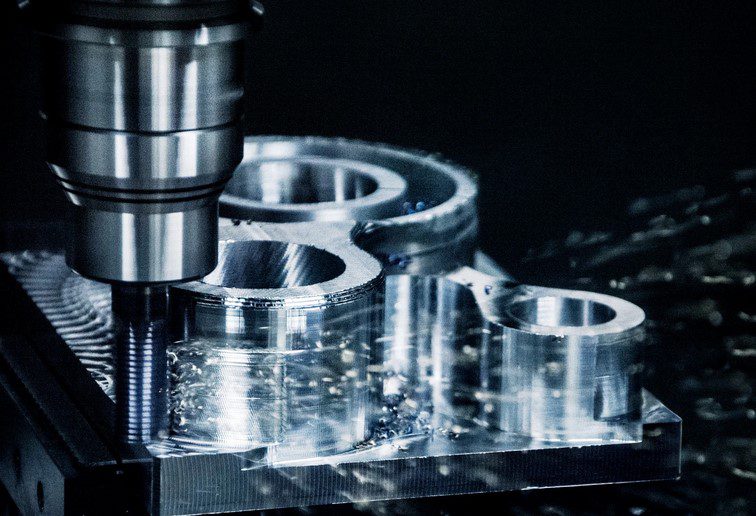

Milling Machine

Metal cutting milling machines, also called metal mills, are cutting tools wherein the component is placed fixed on its workspace. This is where it is exposed to the high-speed rotating cutter that resembles a drill. These metal cutters spin at high RPM and are extremely accurate as far as fine details, dimensions, and corners are concerned. This is why millers often have an extensive application in the process of production work.

Welding Tools

Welding tools use a concentrated ultra-hot flame for chopping through the material. The flame melts its way through thick and hard materials with no physical resistance.